Air quality control is a complex process that involves elected officials, national agencies, regulated industry groups, and the general public. The goal is to protect human health and the environment by controlling the emission of pollutants into the air.

The AQI is computed from air pollutant concentrations measured over some time. The concentrations are converted to a health effect based on epidemiological data. Click here at https://comfortprosheatandair.com/ to learn more about the air quality in your home.

Air Quality Index (AQI)

The Air Quality Index is a measure of how bad the air pollution is in an area. It is calculated by comparing the concentration of certain pollutants to the standards set by local authorities. The index varies by country and region, with different thresholds and calculation methods. It is also based on different pollutants and different combinations of those pollutants. Generally speaking though, the AQI is a good way to compare levels of air pollution across a country or region.

Air Quality Index readings are collected by a network of air quality monitors. The data is fed into an air quality databank which then aggregates the readings and assigns them a rating based on its criteria. Different databases weigh the data differently based on how reliable it is and the type of pollutant being measured.

Typically, a number under 100 means good air quality. When a value is over 100, the authorities must issue an alert for people who are more sensitive to air pollution. When the AQI is above 300, it’s hazardous for everyone and an emergency alert should be issued.

Each AQI level is assigned a color to make it easier for people to understand. Green means conditions are good and pose little or no health risk. Yellow means that air quality is acceptable, but may be unhealthy for some people. The next tier, orange, means that air quality is unhealthy for sensitive groups, and the general public should be aware of potential health impacts. The final tier, maroon, indicates hazardous conditions for all and should trigger an emergency alert.

Air pollution is a global problem and everyone needs to do their part to reduce it. In addition to reducing pollution, citizens need to be aware of the effects of their behavior on the environment. It’s also vital for doctors and healthcare professionals to be aware of a rise in respiratory distress and take measures to protect patients. The AQI is an excellent tool to help achieve these goals, and it’s easy for people to find online or on their local news stations.

Air Pollutants

Air pollutants are chemicals or particulates whose presence in the atmosphere has adverse effects on people and the environment. They are emitted from industrial and residential combustion processes, automobiles, forest fires, and other natural sources. Exposure to high levels of certain air pollutants can lead to respiratory and cardiovascular diseases, a decrease in mental alertness, and damage to plants and animals.

The Clean Air Act requires the EPA to set standards for six common pollutants found in the country including ground-level ozone and particle pollution. These are known as “criteria” pollutants because the association develops health-based and environmental criteria for setting their permissible concentrations.

Particulate matter is a group of very small solid or liquid particles, or droplets, that are less than 10 micrometers in size (millionths of a meter). Airborne suspended particulates are the major source of outdoor air pollution and are caused by coal- or oil-burning power plants, gas stoves and furnaces, residential heating systems, and motor vehicles. People with heart and lung conditions are most susceptible to the harmful effects of these pollutants.

Nitrogen oxides, carbon dioxide, and sulfur dioxide are also common air pollutants. These are emitted by motor vehicles, power plants, refineries, and other industries. When released in large quantities, they can contribute to smog and acid rain.

Biological and chemical compounds, such as dioxins, phenols, and formaldehyde, are another group of air contaminants. They can contaminate the water supply and cause disease in humans, as well as damage the ecosystem. These contaminants are mainly produced in industrial processes and by forest fires and can be carried long distances by wind.

Hazardous air pollutants, or HAPs, are those that are known or suspected to cause cancer or other serious health effects. These include benzene, which is emitted during gasoline combustion; perchloroethylene, which is emitted by some dry cleaning facilities; and methylene chloride, which is used as a solvent and paint stripper by many industries.

The organization has established national air quality standards for these and other pollutants, as well as for background concentrations of pollutants in the air. It also works with state, local, and tribal governments to reduce the emissions of HAPs into the environment. It provides access to ambient air quality data from more than 10,000 stations in the country. The site also contains meteorological data and other descriptive information about each station.

Air Quality Monitoring

Air pollution can affect our health, and monitoring is essential for controlling it. Air quality monitoring involves measuring various pollutants present in the air and reporting them to authorities. The data can be used to identify areas with poor air quality and implement control measures to improve it. This can lead to improved health outcomes for the population and a better quality of life.

The national air monitoring program collects data on criteria pollutants, including carbon monoxide, oxides of nitrogen (NO2 and NO3), ozone, particulate matter with aerodynamic diameters of less than 2.5 micrometers (PM2.5), sulfur dioxide, and volatile organic compounds. The program is carried out by state and local air pollution control agencies under its oversight.

Air pollution levels can vary greatly from place to place, as a result of weather conditions, geographic patterns, and sources of pollution. Many communities have established air quality districts to monitor air quality and enforce relevant standards. They have a website where you can check real-time air pollution data for various locations in the country. The data are displayed using a color-coded system, which shows the current level of ozone and particle pollution in the area.

A major challenge in air pollution monitoring is the decision of where to place monitors. This is a critical factor in determining whether the information collected can be trusted and used to inform public health decisions. There is evidence that some local regulators use their discretion to encourage economic development by placing monitors in areas where the readings are low enough to allow new construction projects without limiting growth or economic potential. This may serve the local economy but conceals localized environmental injustice and puts residents at risk.

Air quality monitoring systems must be designed to meet strict requirements, and the resulting infrastructure is expensive and complex to maintain. However, recent advances in sensor technology have made it possible to build and deploy more affordable sensors with new capabilities. Some of these sensors are now capable of measuring air toxics, which is more dangerous for humans and ecosystems than ozone or particles and can be difficult to measure with traditional monitors.

Control Measures

Air quality control measures are strategies that can be used to reduce exposure to a hazardous substance. These can include administrative controls (e.g. limiting the number of workers in a specific area) and engineering controls (e.g. installing a ventilation system to carry away contaminants). In addition, personal protective equipment can be used to prevent exposure to the contaminant. However, the best way to control exposure to a hazardous substance is to remove it from the workplace altogether. For example, replacing the use of abrasive or toxic materials with less hazardous ones can be an effective control measure.

In the country, air pollution is regulated by state and local governments. State-level regulations are set using data collected by state agencies and a peer review process. Local regulations are set by city and town officials, with input from residents. The regulations are designed to protect public health and the environment.

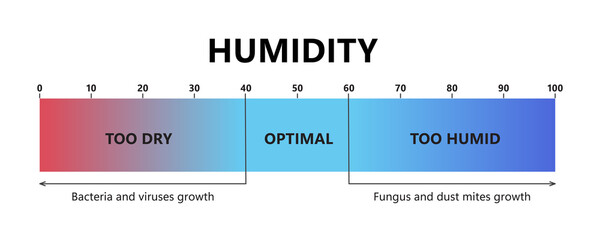

Several different types of air monitoring systems are used to measure air quality. These systems can be as simple as a stationary monitor that records ambient air temperature, humidity, and particulate levels, or as complex as a multi-sensor, mobile measurement platform with remote real-time data transmission capabilities.

Air pollutants can come from a variety of sources, such as traffic and combustion emissions, industrial production processes, and natural phenomena like fog or sand storms. The most common sources, however, are human activities in urban areas. These activities can cause high levels of nitrogen dioxide (NO2), fine particulate matter, and ozone.

One of the most important functions is to identify the sources of these pollutants and their impact on people. This is done through the application of standard reference measurements and normalized monitoring methods, and by analyzing data from existing contaminant exposure databases.

Another function is to monitor local emissions and take control measures when necessary. For example, if the concentrations of certain criteria pollutants are high in a particular area, they can issue an air quality alert. This alert can be based on the criteria pollutants or other pollutants that pose a threat to public health, such as volatile organic compounds.